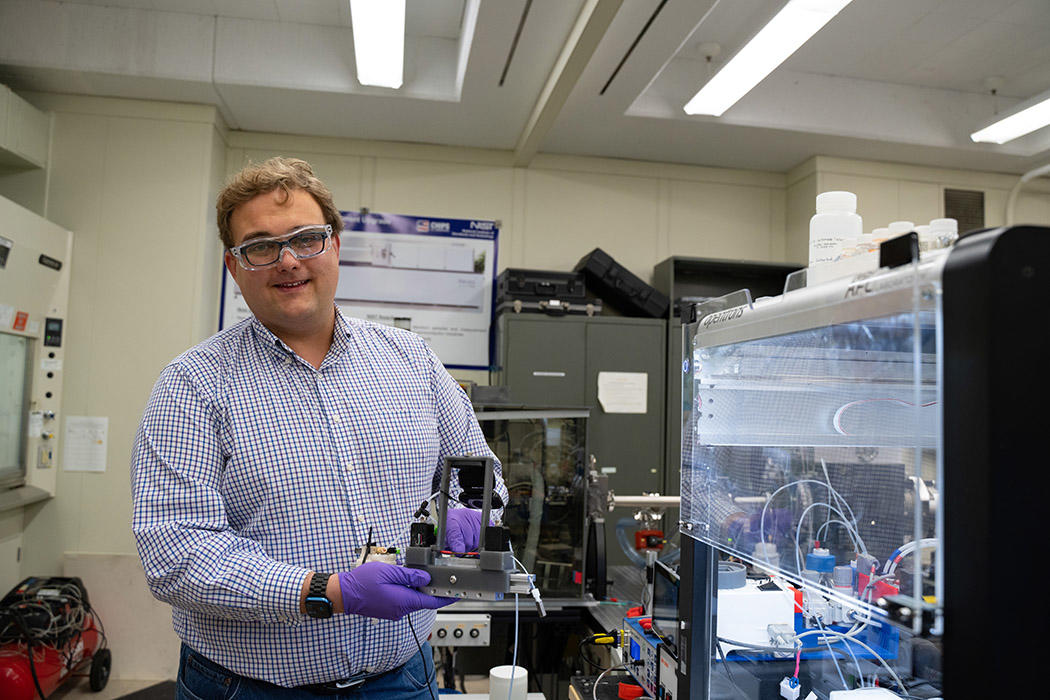

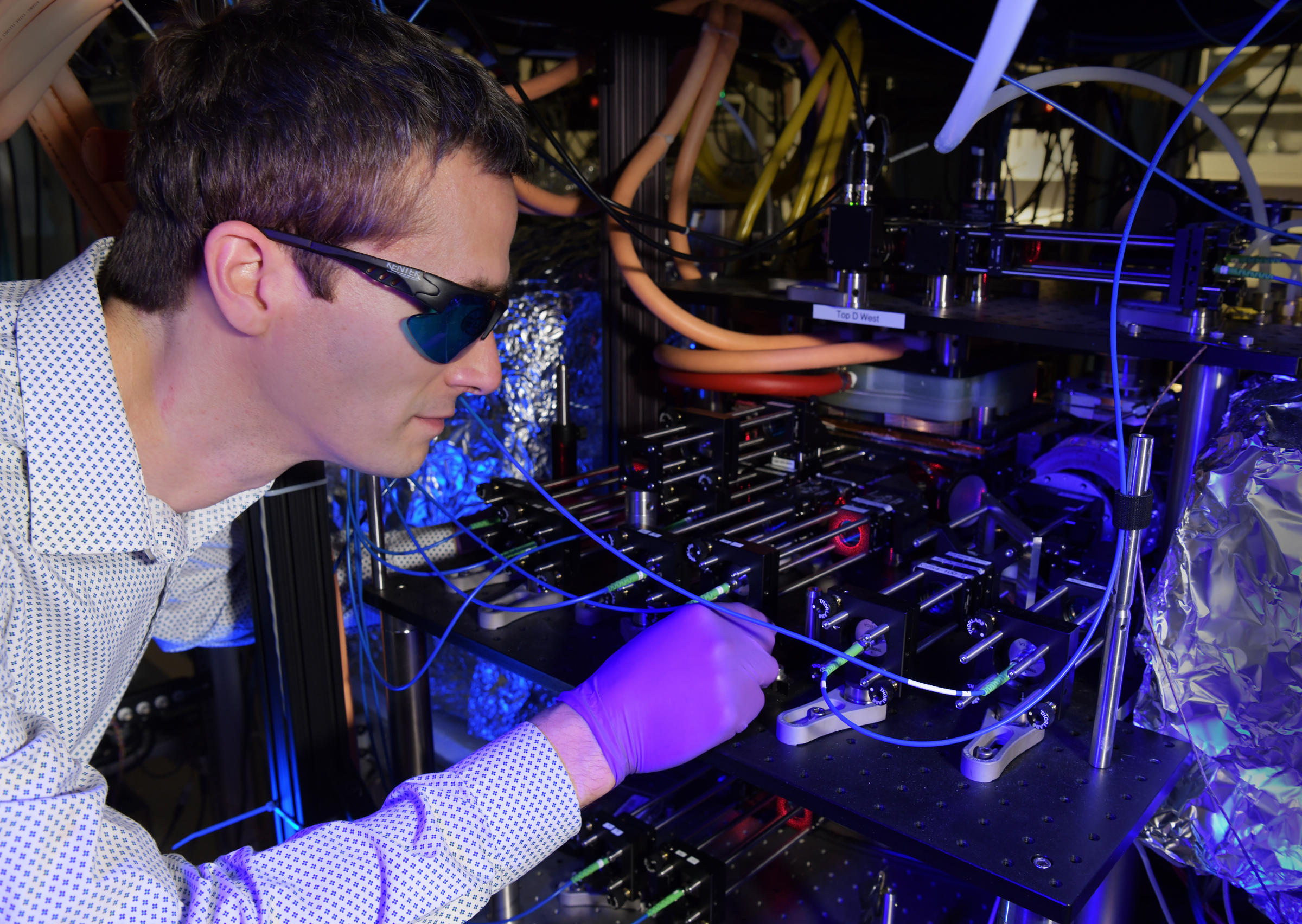

Reformulating a client product can take months of analysis and some huge cash. Within the Autonomous Formulation Laboratory at NIST, AI helps develop “recipes” that may then be examined as a part of product improvement.

Credit score: M. King/NIST

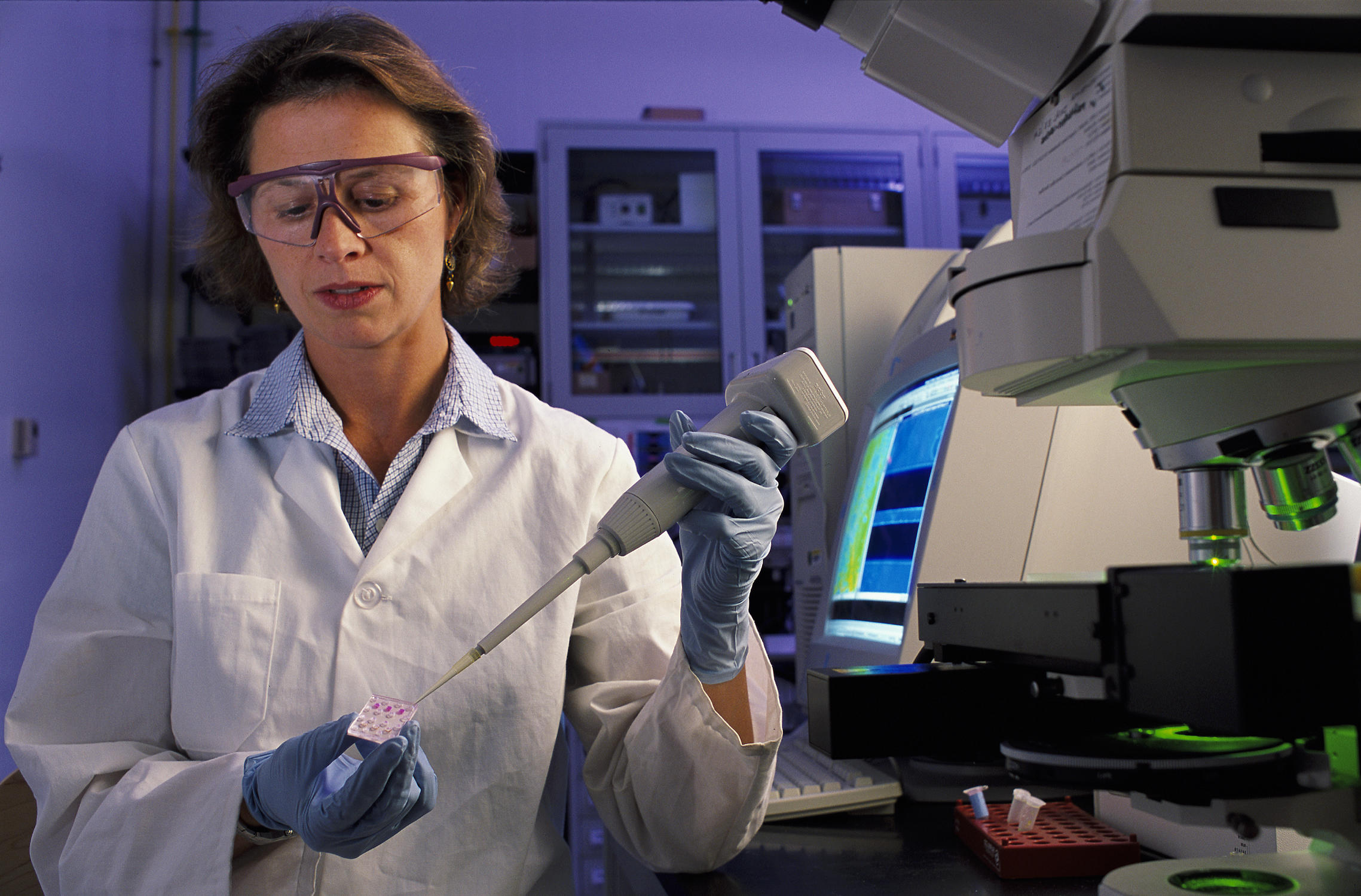

Each time you squeeze toothpaste onto your toothbrush, spray fragrance in your pores and skin, or swallow a tablet, you’re utilizing the results of a fastidiously crafted recipe made in a lab. These are known as formulations.

Formulations aren’t simply easy mixtures — they’re advanced preparations of components designed to work collectively in particular methods.

Getting the recipe proper can imply the distinction between a product that sits on the shelf (or by no means makes it to the shelf) and one which adjustments lives.

Right here at NIST, we’re revolutionizing how scientists create and enhance formulations. We hope the outcome will likely be higher merchandise you employ each day.

The method combines robotics, synthetic intelligence and evaluation of superior supplies. For instance, we are able to use neutrons or X-rays to take footage of how molecules tens of millions of instances smaller than a human hair are organized in supplies.

It’s not nearly making higher merchandise. It’s about making them in methods which can be quicker and extra environment friendly whereas leaving a lighter footprint on well being and the surroundings. This occurs in our Autonomous Formulation Laboratory (AFL) at NIST’s campus in Gaithersburg, Maryland.

How Your Merchandise Are Made Now

Let’s say you personal a shampoo firm, and a key ingredient in your shampoo is not out there as a consequence of provide chain points.

You now need to remake your formulation to place in a alternative ingredient. However what ingredient? How a lot of it? What if that new ingredient has an unintended consequence that impacts different components of the recipe?

That is the problem of product formulation in the present day. Reformulating a client product can take months of analysis and some huge cash. It usually requires trial and error or professional know-how. Whereas that information is efficacious, consultants might have problem adapting to new or altering components.

Credit score:

M. King/NIST

However as a scientific group, we are able to do higher. NIST has consultants who use instruments to look at the construction of supplies and measure them on the smallest scales. However the sheer variety of samples would make this difficult to do in a conventional formulation lab.

Enter AI.

An Clever, Interactive Loop

Right here’s how this course of works:

Step 1: Precision Mixing

Very like cooking, we begin by gathering the components. As a substitute of placing them in an oven, we put them into small vials in regards to the dimension of a movie canister and inform a pc about what they’re. The pc then controls a robotic system geared up with a pipette. This pc exactly measures and mixes tiny quantities of chemical substances from totally different vials. The quantity of combination is minuscule — about 30 microliters, lower than a dot of ink from a fine-tip pen.

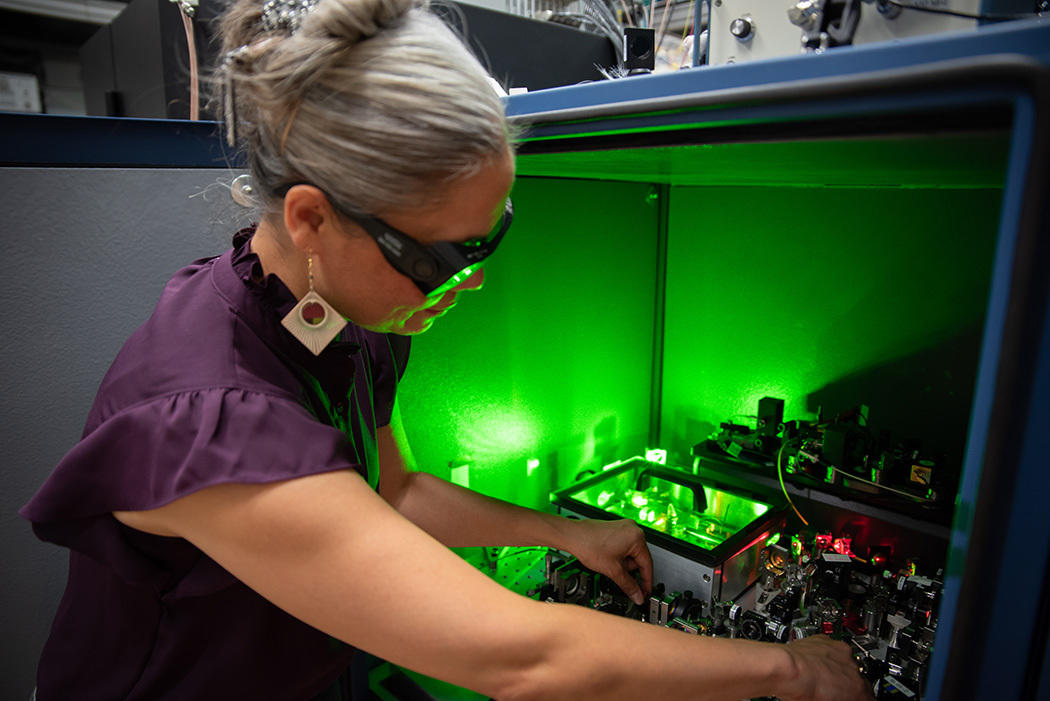

Step 2: Superior Structural Evaluation

As soon as the pattern is ready, we analyze it at a really detailed stage, utilizing gear that works like a complicated microscope. We name these superior scattering methods.

These methods permit us to watch how totally different chemical substances set up themselves into bigger buildings throughout the formulation. We will then make predictions about how merchandise will behave as soon as our “recipe” is made.

These scattering methods normally occur at a neutron supply, such because the NIST Middle for Neutron Analysis on our Gaithersburg campus. Additionally they typically occur at a machine a few half-mile lengthy that makes extremely brilliant X-rays, referred to as a synchrotron.

Step 3: AI-Pushed Optimization and Studying

Right here’s the place the magic occurs. Throughout the formulation measurement course of, we acquire a wealth of knowledge and feed it into a man-made intelligence system. The AI analyzes the knowledge, learns about it and predicts which formulation construction will work greatest given the producer’s targets. It then instructs the robotic system to create this new formulation based mostly on what it’s realized from previous duties.

However it doesn’t cease there. The robotic analyzes the brand new formulation and feeds the outcomes again into the AI. With every iteration, the AI learns, refines its understanding and makes more and more refined predictions. It’s as if the system is considering, studying and evolving its method in actual time.

Credit score:

M. King/NIST

This creates a loop of experimentation and enchancment, dramatically accelerating the event course of for medicines and different client merchandise. What might need taken months or years of trial and error can now be achieved in hours or days.

After all, AI is just not excellent, and you’ll’t belief it with out intensive product testing. The businesses concerned on this course of nonetheless check their merchandise. AI helps them develop their “recipes” rather more shortly and simply than they may earlier than.

Actual-World Impression

In a current collaboration with a pharmaceutical firm, the AFL tackled a posh formulation situation in simply hours — a course of that may have taken months utilizing conventional strategies.

By specializing in the structural association of the formulation’s parts and studying from every strive, the crew may shortly establish and resolve points affecting the drug’s efficiency.

However the AFL’s affect extends past prescribed drugs.

We’re serving to producers enhance a variety of merchandise by optimizing their structural compositions. This is applicable to every thing from shampoos and paints to automotive fluids and cleansing detergents.

The AFL can deal with just about any liquid formulation proper now. We’re exploring methods to adapt it to investigate structured solids sooner or later.

Making a Distinction With Industrial Science

Like lots of people who do one of these work, I really like an fascinating downside.

After I first got here to NIST as a postdoctoral researcher, I used to be fairly naive. I’d labored within the specialty chemical business for a time, however I believed that almost all industrial issues have been nearer to engineering than deep science.

However I began engaged on this mission that entails pulling the salt out of seawater. That is how consuming water is made in lots of components of the Center East and South Africa. It’s getting used at an enormous scale, and nobody actually understands why it really works.

It was so eye-opening to see this unimaginable course of liable for maintaining tens of millions of individuals alive, and there are nonetheless basic questions on why it really works. These questions maintain us again from engineering one thing higher.

By that work, I acquired concerned with a consortium of corporations that works with NIST, known as nSoft. I shortly realized that this type of downside was pretty typical.

Wherever I appeared within the members’ science — from detachable adhesive strips for hanging footage on the wall to cleaning soap bubbles — there have been deep, foundational questions in regards to the universe concerned. Groups of a few of the brightest folks I’ve ever met are taking a look at these questions and attempting to grasp. I used to be transformed.

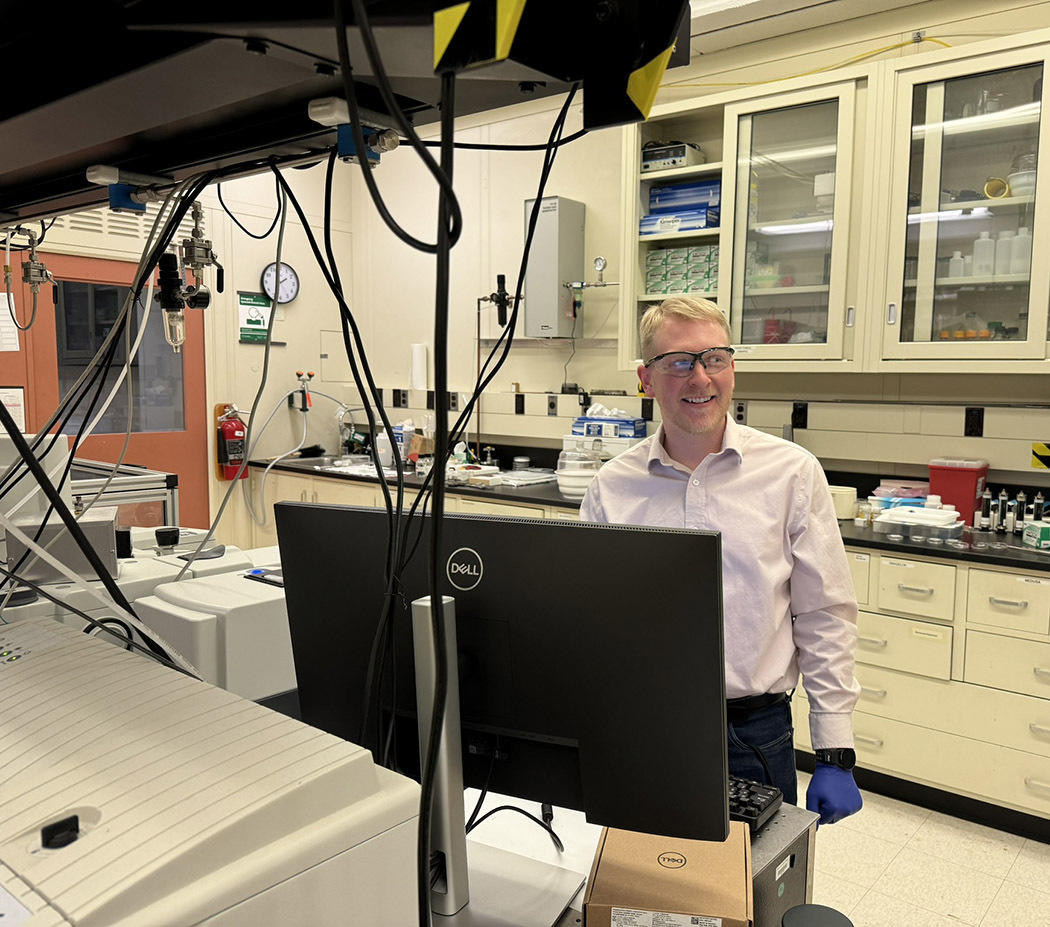

Credit score:

M. King/NIST

Simply earlier than the pandemic, my colleague Tyler Martin began a mission that concerned shopping for and constructing robots for automated resolution mixing. Tyler invited me to have a look at the {hardware} and assist with just a few small points. When the units arrived, I stored slipping out to the lab to work on the software program for them and tinker with how they moved options round. I needed to grasp and exploit the capabilities to get actual outcomes. Ultimately, this “interest” grew to become my primary scientific focus.

This mission has been so fulfilling to me. We’re getting nice outcomes and actually fixing significant issues with the businesses we work with. What began as a small crew of two has grown right into a community of scholars, postdocs, scientific collaborators and different facility scientists who span the globe.

If you get to come back to work and construct and troubleshoot robots to deal with basic questions in regards to the universe that affect billions of individuals, you will have a fairly nice job. I’m particularly fortunate to work with the implausible crew we’ve constructed; there’s actually nothing I’d relatively be doing. I’m dwelling my 10-year-old self’s dream life — constructing robots and altering the world.

Wanting Forward

Whereas this method has super promise, we have to scale it up in order that extra corporations can use it of their product formulation processes.

We’re publishing our methodology for anybody who desires to recreate it. We’re additionally working with the corporations in the nSoft consortium and offering them with hands-on help in recreating this in different amenities like ours across the nation.

As this know-how continues to evolve, we are able to sit up for more practical and progressive merchandise throughout a variety of industries — all due to a system that by no means stops studying and bettering.