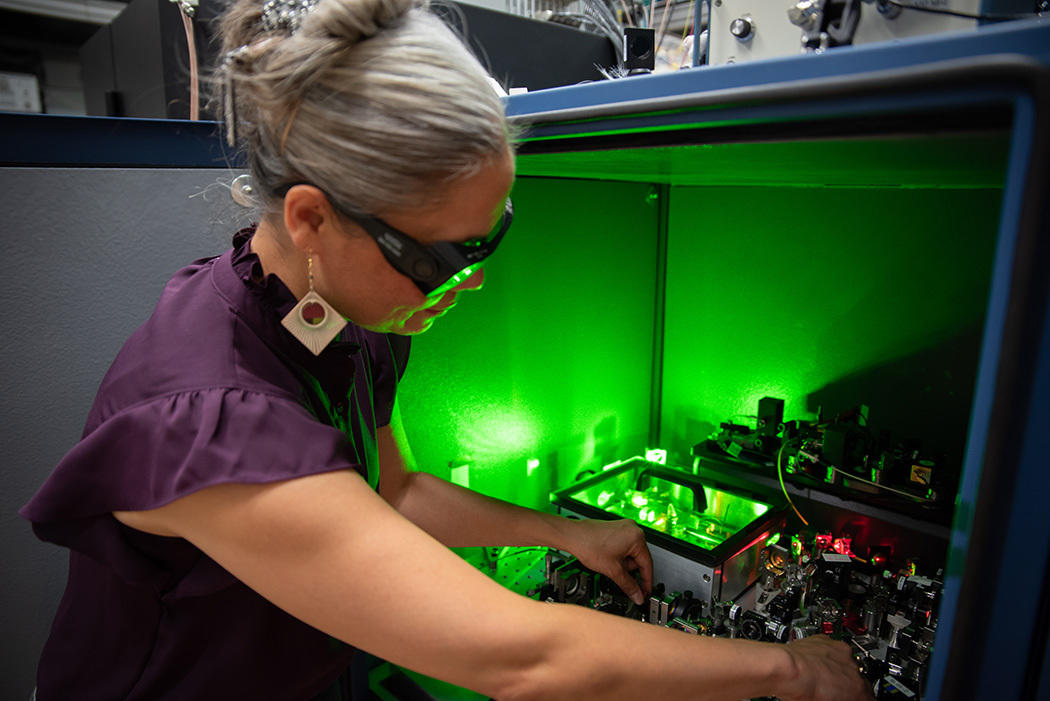

NIST researcher Thomas P. Forbes is working to make sure 3D drug printers work as designed.

Credit score: R. Eskalis/NIST

Chocolate-flavored drugs for youngsters who hate taking drugs.

A number of medication mixed into one every day capsule for seniors who’ve hassle remembering to take their medicines.

Medicine printed at your native pharmacy at personalised dosages that finest fit your well being wants.

These are just some potential benefits of 3D drug printing, a brand new system for manufacturing medication and coverings on-site at pharmacies, well being care services and different distant areas.

In 2015, the Meals and Drug Administration permitted the primary 3D-printed drug, Spritam (levetiracetam), for epilepsy. A number of different producers and drug firms are creating their very own ones.

However the widespread adoption of 3D drug printing would require stringent high quality management measures to make sure that folks get the precise medicine and dosage. Even a tiny mismeasurement of a drug’s ingredient throughout the printing course of might endanger a affected person’s well being.

In a new analysis paper, NIST analysis scientist Thomas P. Forbes assesses varied approaches to making sure that 3D drug printers work as designed. The journal article applies a “high quality by design” evaluation to guage the perfect procedures and protocols to make sure that 3D printers produce medication on the appropriate dosages and with the right combination of chemical compounds.

Although varied strategies exist for remotely printing medication, Forbes targeted on some of the widespread: inkjet printers and related programs that may print personalised medicine on demand.

Like inkjet printers in houses, although bigger, the printer has nozzles that deposit the drug’s liquified supplies, or inks, into tiny wells on a tray or immediately into capsules. By way of freeze-drying and different processes, the liquid will be become a pill or powder poured right into a capsule. It will also be evaporated onto a skinny movie that dissolves within the mouth.

Forbes’ paper doesn’t make any suggestions. As a substitute, his analysis identifies and exams a number of potential strategies and strategies for sustaining high quality management in 3D drug printing.

The Taking Measure weblog spoke with Forbes about his analysis.

What are a number of the benefits of 3D drug printing?

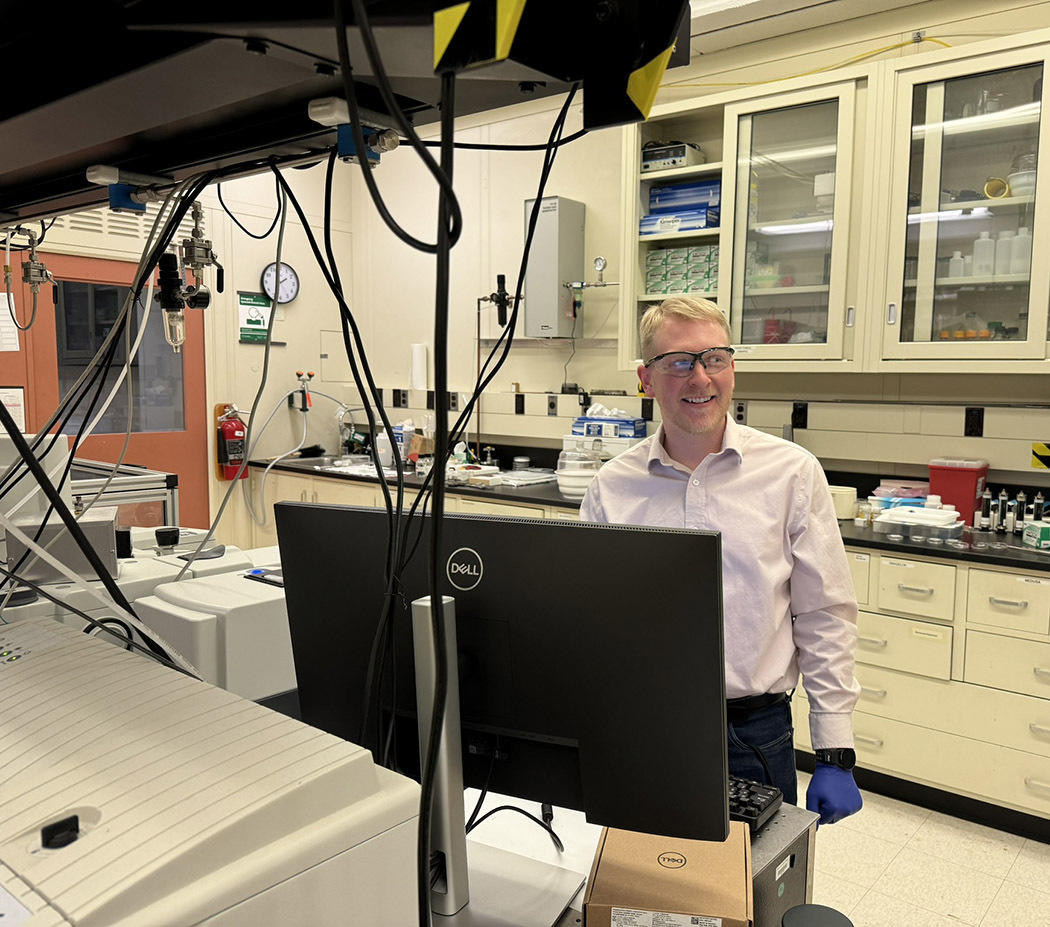

Credit score:

R. Eskalis/NIST

When your physician writes a prescription, she is aware of medication can be found in sure dosages, and she or he’ll select the dosage she thinks is finest for you. Some medication are available in many sizes, whereas others are available in only one.

3D printing allows you to individualize the dosage. You are able to do it primarily based on the individual’s age, well being, even their immune system or genetic profile.

You may also personalize the shape that the drugs takes. Some sufferers might want a liquid to a capsule, for instance. There’s additionally been analysis on polypills, which mix a number of drugs right into a single drug. And a few scientists have targeted on the advantages for youngsters who don’t wish to take their drugs. With 3D printing, you possibly can create medication formed like starfishes or ones that style like chocolate.

3D drug printing additionally has the massive potential to alter vaccine distribution.

Sure, there’s loads of curiosity in offering “point-of-care” areas the place the vaccines can be printed close to the place they’re administered.

You’d nonetheless have a bigger facility making the uncooked supplies, however you could possibly be far more agile and faster in getting the vaccine to the general public. This is able to be vastly useful throughout one other pandemic.

Your analysis focuses on high quality management and measurements in 3D drug printing.

Sure, we might want to know that these 3D printers are working appropriately. They should print the right dosages with the precise substances. So, we are going to want on-site strategies of taking and validating measurements. That is an space the place NIST has a substantial amount of experience.

In your journal article, you break down the standard management course of step-by-step. Can you’re taking us by that?

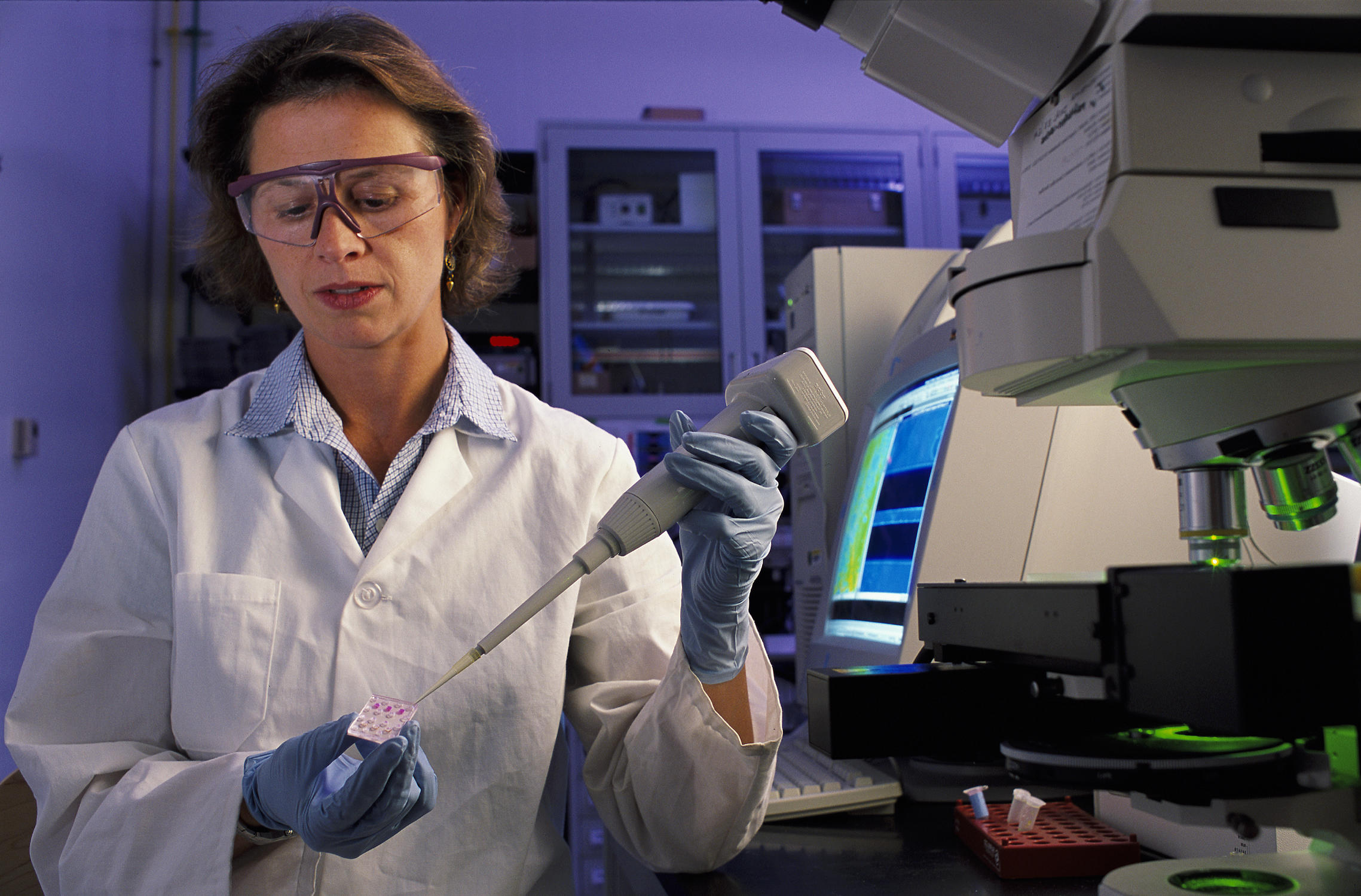

Credit score:

R. Eskalis/NIST

It begins with the supply of the printing ink to the distant location. That you must affirm it hasn’t degraded, evaporated or been uncovered to uncommon temperatures. You wish to affirm it’s nonetheless good.

We used a method known as ultraviolet-visible (UV-Vis) spectroscopy. There at the moment are comparatively cheap tabletop and even handheld UV-Vis spectrometers in the marketplace. They work by shining ultraviolet and visual mild by your pattern. How the pattern absorbs them tells you about its chemical composition.

Subsequent, we checked out how one can confirm your printer is working appropriately. Many industrial printers have LEDs beneath the person nozzles that print the ink for the medication. Each time the nozzle releases a drop of ink, it breaks the movement of sunshine, which is detected by a sort of sunshine detector referred to as a photodiode.

The photodiode will detect if the nozzle stops releasing liquid since you’ve run out of ink. If there’s a blockage within the nozzle or perhaps a piece of mud inflicting irregularities within the movement of ink drops, that can even be detected. In our exams, we discovered the LEDs and photodiodes carried out properly.

What about confirming that you simply’ve printed the right amount of the drug?

That’s tough. You want a nondestructive approach of confirming the right dosage. We’re engaged on this proper now. It’s the subsequent huge step.

What’s the last word aim right here?

We’d like to supply a sequence of voluntary protocols or suggestions for high quality management and measurement accuracy in 3D drug printing. We’ll probably work collaboratively with different teams, resembling American Society for Testing and Supplies or United States Pharmacopeia, to launch these.

If 3D drug printing turns into extensively adopted, we wish to be able to assist each trade and regulatory companies with a measurement science basis.