BBC Information

Getty Photographs

Getty PhotographsIt is a brilliant spring morning in Hanover, Germany, and I am on my option to meet a robotic.

I’ve been invited to see the G1, a humanoid robotic constructed by Chinese language agency, Unitree, on the Hannover Messe, one of many world’s largest industrial commerce reveals.

Standing at about 4’3″ (130cm), G1 is smaller and extra reasonably priced than different humanoid robots available on the market, and has such a extremely fluid vary of movement and dexterity that movies of it performing dance numbers and martial arts have gone viral.

At the moment the G1 is being managed remotely by Pedro Zheng, the Unitree gross sales supervisor.

He explains that clients should program every G1 for autonomous features.

Passers-by cease and actively attempt to have interaction with the G1, which can’t be stated for lots of the opposite machines being proven off within the cavernous convention room.

They attain out to shake its hand, make sudden actions to see if it’ll reply, they snort when G1 waves or bends backwards, they apologise in the event that they stumble upon it. There’s one thing about its human form that, uncanny as it’s, units folks relaxed.

Permit Google YouTube content material?

Unitree is only one of dozens of corporations all over the world creating robots which have a human kind.

The potential is large – for enterprise it guarantees a workforce that does not want holidays or pay rises.

It is also the final word home equipment. In any case, who would not desire a machine that might do the laundry and stack the dishwasher.

However the expertise continues to be a way off. Whereas robotic arms and cell robots have been widespread in factories and warehouses for many years, circumstances in these workplaces may be managed and staff may be stored secure.

Introducing a humanoid robotic to a much less predictable atmosphere, like a restaurant or a house, is a way more tough drawback.

To be helpful humanoid robots must be robust, however that additionally makes them probably harmful – merely falling over on the improper time may very well be hazardous.

A lot work must be accomplished on the substitute intelligence that might management such a machine.

“The AI merely has not but reached a breakthrough second,” a Unitree spokesperson tells the BBC.

“At the moment’s robotic AI finds primary logic and reasoning – comparable to for understanding and finishing complicated duties in a logical method – a problem,” they stated.

In the intervening time their G1 is marketed at analysis establishments and tech corporations, who can use Unitree’s open supply software program for improvement.

For now entrepreneurs are focussing their efforts on humanoid robots for warehouses and factories.

The very best profile of these is Elon Musk. His automobile firm, Tesla, is creating a humanoid robotic referred to as Optimus. In January he stated that “a number of thousand” will likely be constructed this yr and he expects them to be doing “helpful issues” in Tesla factories.

Different carmakers are following the same path. BMW lately launched humanoid robots to a US manufacturing unit. In the meantime, South Korean automobile agency Hyundai has ordered tens of hundreds of robots from Boston Dynamics, the robotic agency it purchased in 2021.

Thomas Andersson, founding father of analysis agency STIQ, tracks 49 corporations creating humanoid robots – these with two legs and arms. In case you broaden the definition to robots with two arms, however propel themselves on wheels, then he seems at greater than 100 corporations.

Mr Andersson thinks that Chinese language corporations are more likely to dominate the market.

“The provision chain and the whole ecosystem for robotics is large in China, and it is very easy to iterate developments and do R&D [research and development],” he says.

Unitree underlines that benefit – its G1 is reasonable (for a robotic) with an marketed worth of $16,000 (£12,500).

Additionally, Mr Andersson factors out, the funding favours Asian nations.

In a current report STIQ notes that nearly 60% of all funding for humanoid robots has been raised in Asia, with the US attracting a lot of the relaxation.

Chinese language corporations have the additional advantage of help from the nationwide and native authorities.

For instance, in Shanghai there’s a state-backed coaching facility for robots, the place dozens of humanoid robots are studying to finish duties.

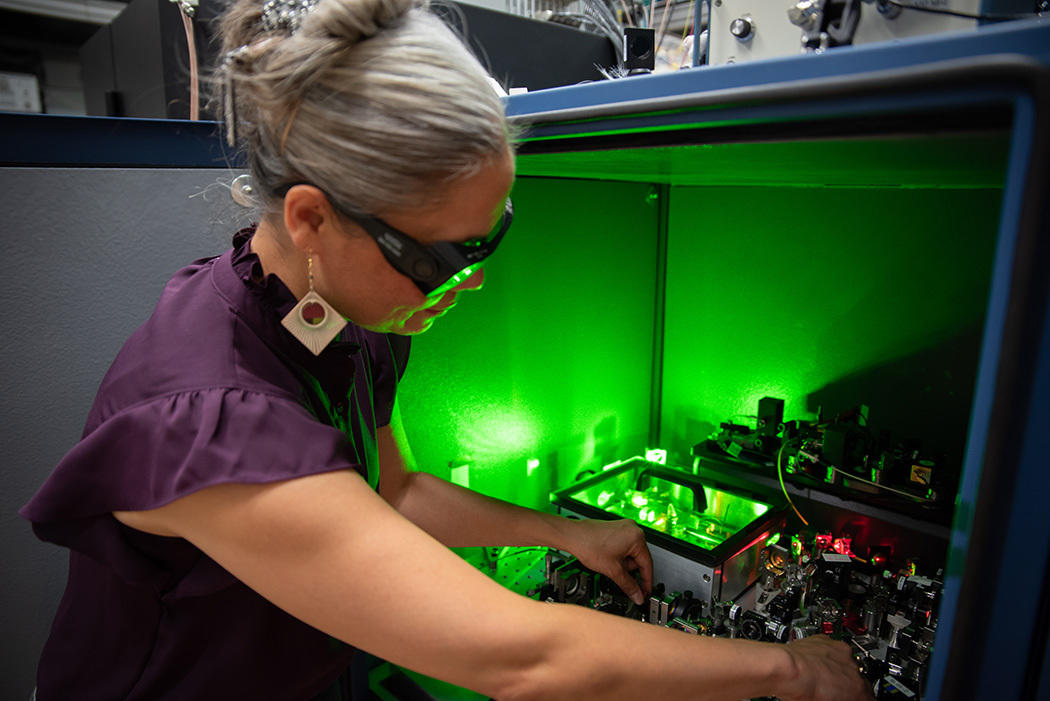

Getty Photographs

Getty PhotographsSo how can US and European robotic makers compete with that?

Bristol-based Bren Pierce has based three robotics corporations and the most recent, Kinisi has simply launched the KR1 robotic.

Whereas the robotic has been designed and developed within the UK, it is going to be manufactured in Asia.

“The issue you get as a European or American firm, you need to purchase all these sub-components from China within the first place.

“So then it turns into silly to purchase your motors, purchase your batteries, purchase your resistors, shift all of them midway all over the world to place collectively when you would simply put all of them collectively on the supply, which is in Asia.”

In addition to making his robots in Asia, Mr Pierce is holding prices down by not going for the complete humanoid kind.

Designed for warehouses and factories, the KR1 doesn’t have legs.

“All of those locations have flat flooring. Why would you need the added expense of a really complicated kind issue… when you would simply put it on a cell base?” he asks.

The place doable, his KR1 is constructed with mass-produced elements – the wheels are the identical as you’ll discover on an electrical scooter.

“My philosophy is purchase as many issues as you’ll be able to off the shelf. So all our motors, batteries, computer systems, cameras, they’re all commercially out there, mass produced elements,” he says.

Like his opponents at Unitree, Mr Pierce says that the true “secret sauce” is the software program that enables the robotic to work with people.

“A number of corporations come out with very high-tech robots, however you then begin needing a PhD in robotics to have the ability to truly set up it and use it.

“What we’re making an attempt to design is a quite simple to make use of robotic the place your common warehouse or manufacturing unit employee can truly learn to use it in a few hours,” Mr Pierce says.

He says the KR1 can carry out a process after being guided by means of it by a human 20 or 30 occasions.

The KR1 will likely be given to pilot clients to check this yr.

Kinisi

KinisiSo will robots ever get away of factories into the house? Even the optimistic Mr Pierce says it is a great distance off.

“My long run dream for the final 20 years has been constructing the every part robotic. That is what I used to be doing my PhD work in I do suppose that’s the finish objective, nevertheless it’s a really difficult process,” says Mr Pierce.

“I nonetheless suppose ultimately they are going to be there, however I believe that is a minimum of 10 to fifteen years away.”